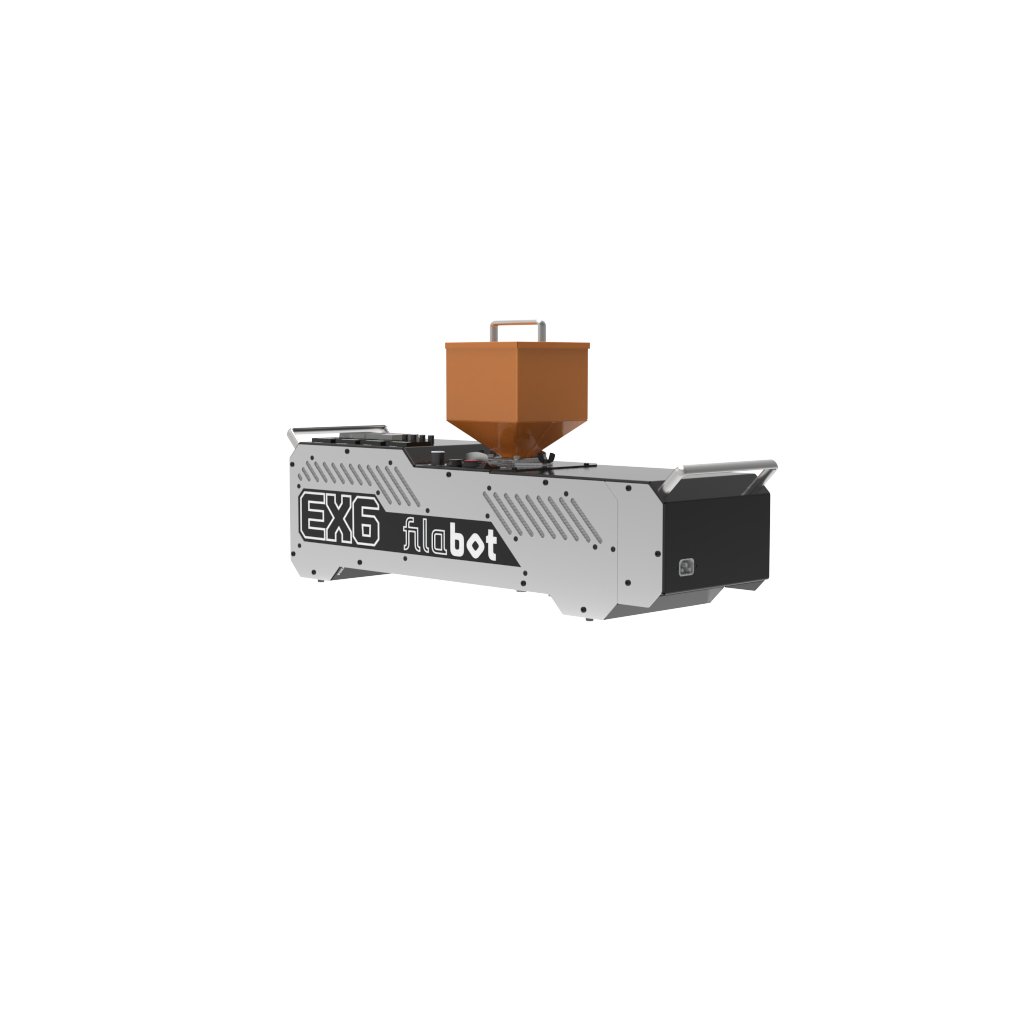

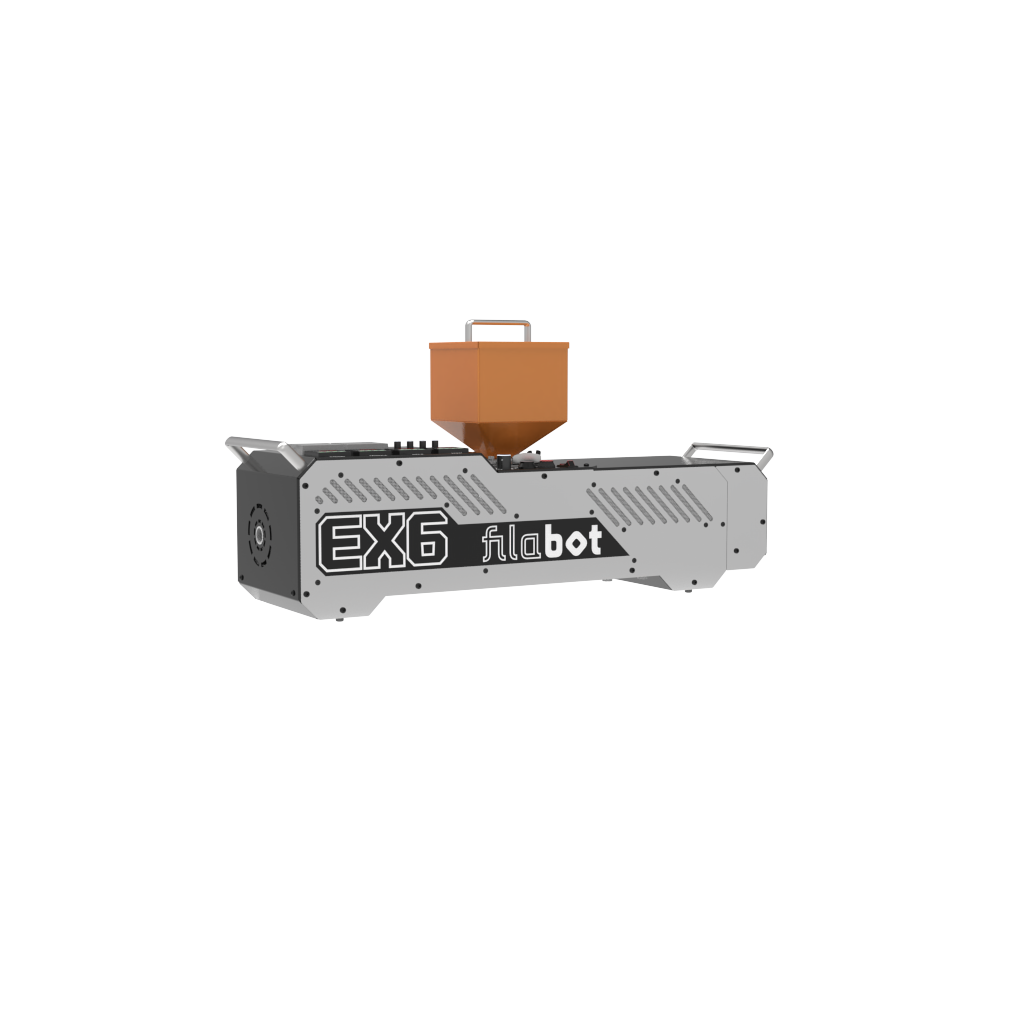

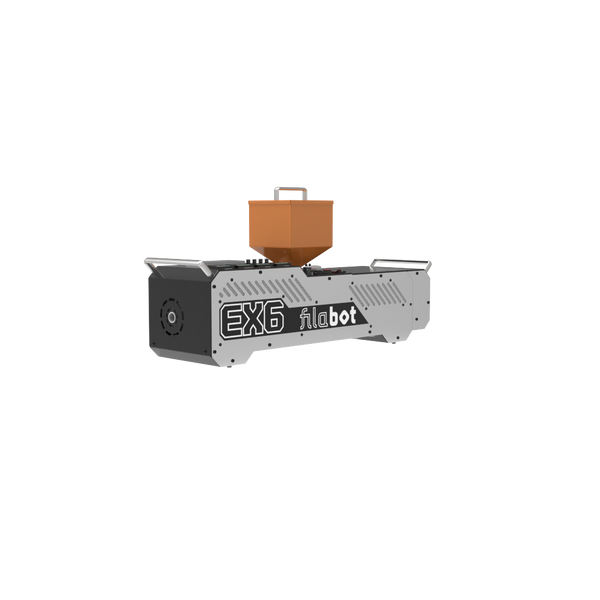

Filabot

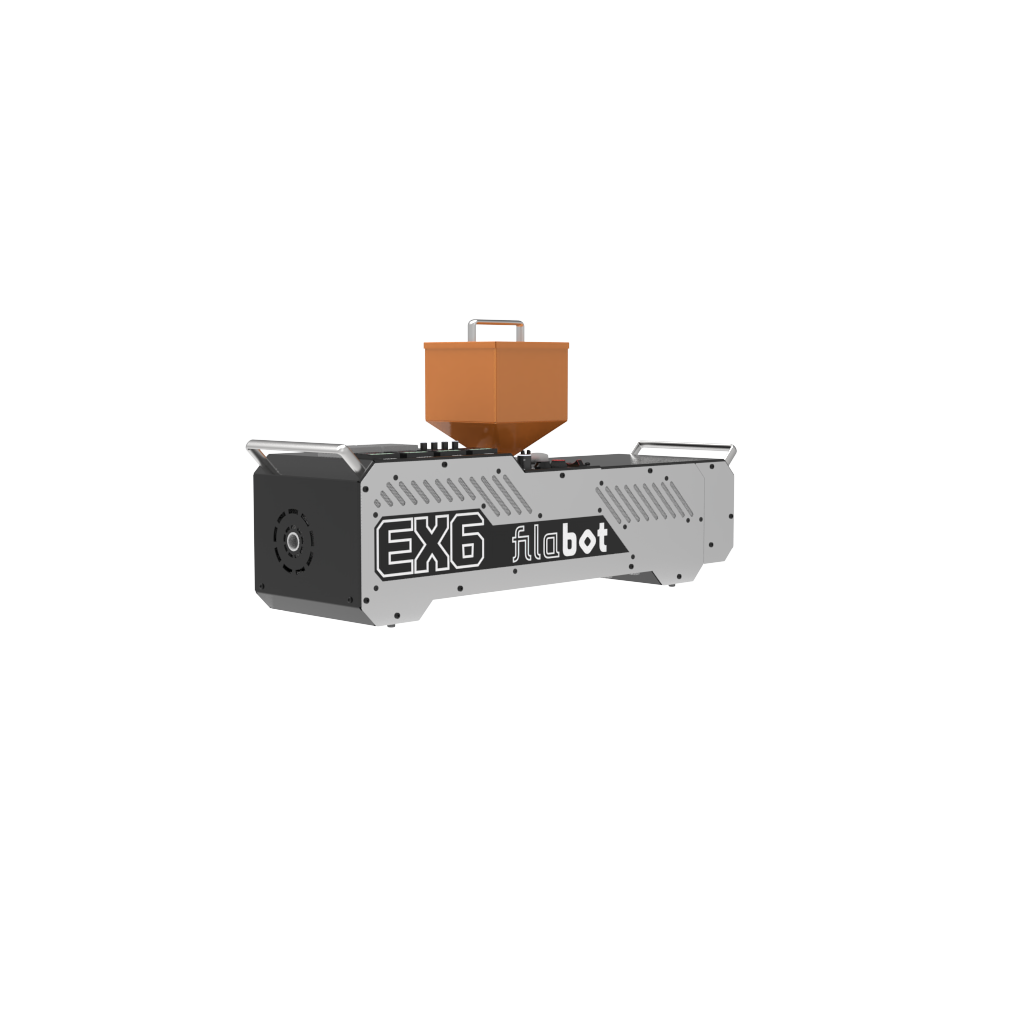

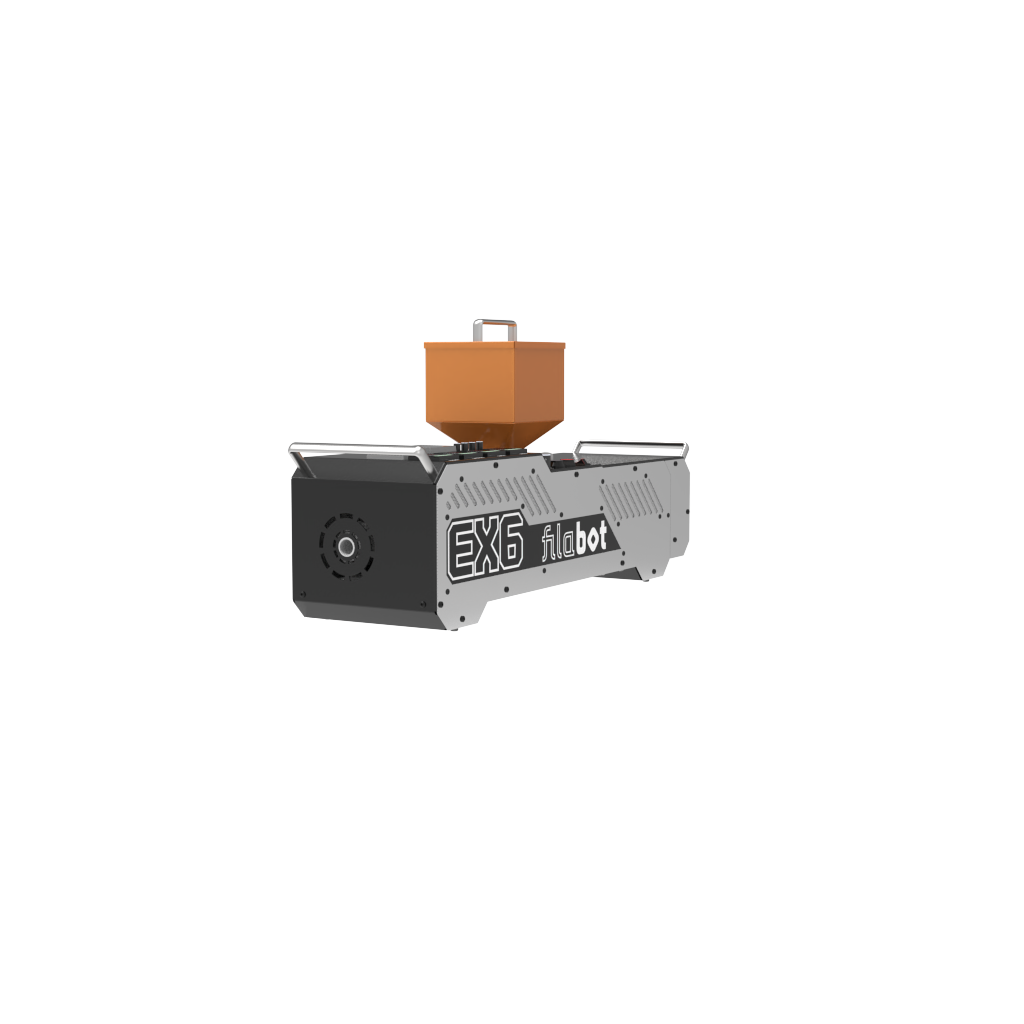

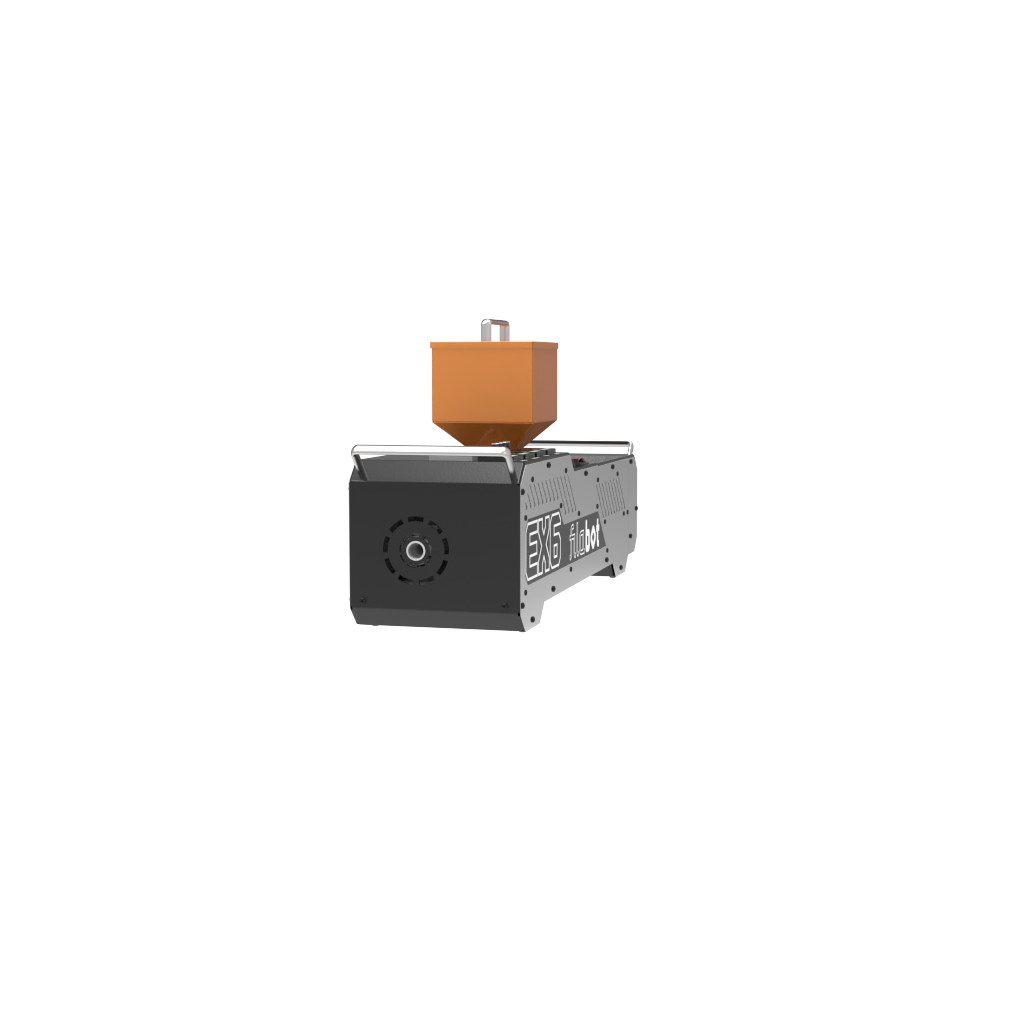

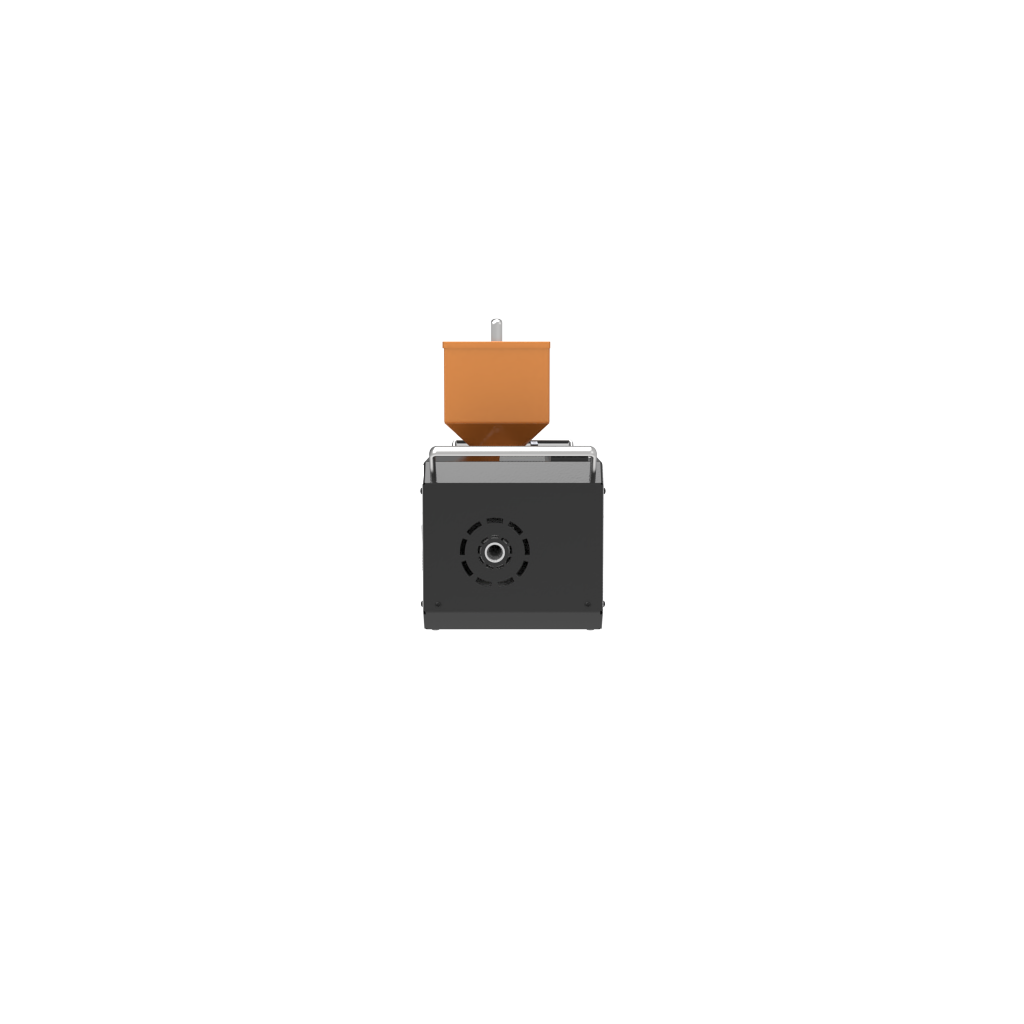

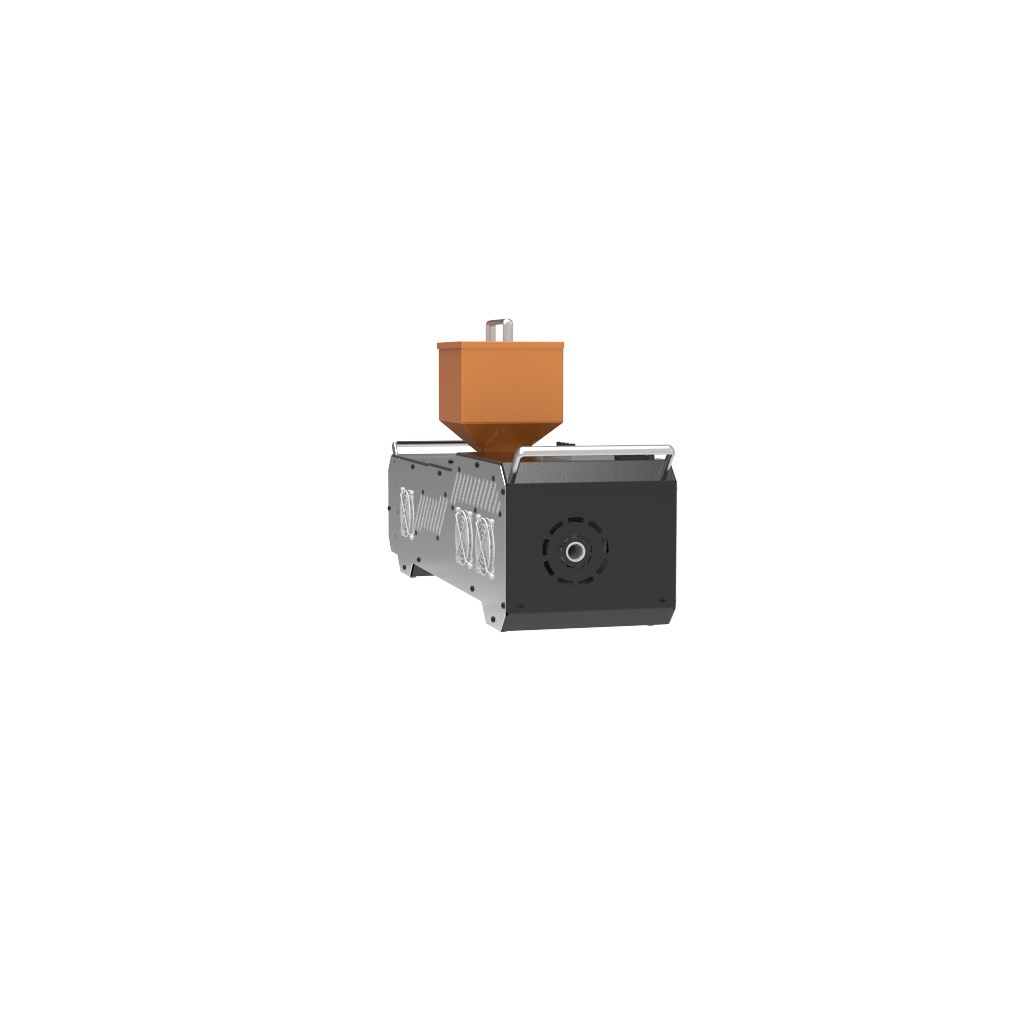

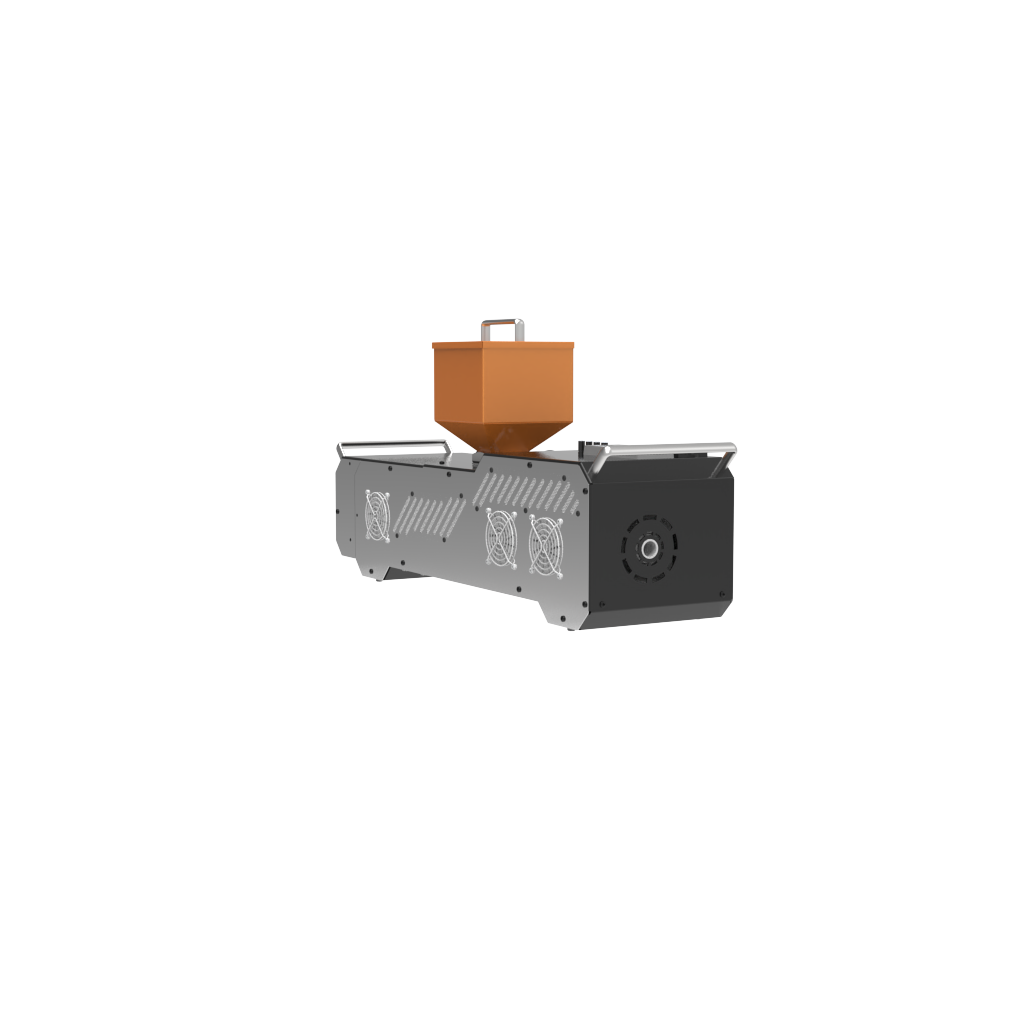

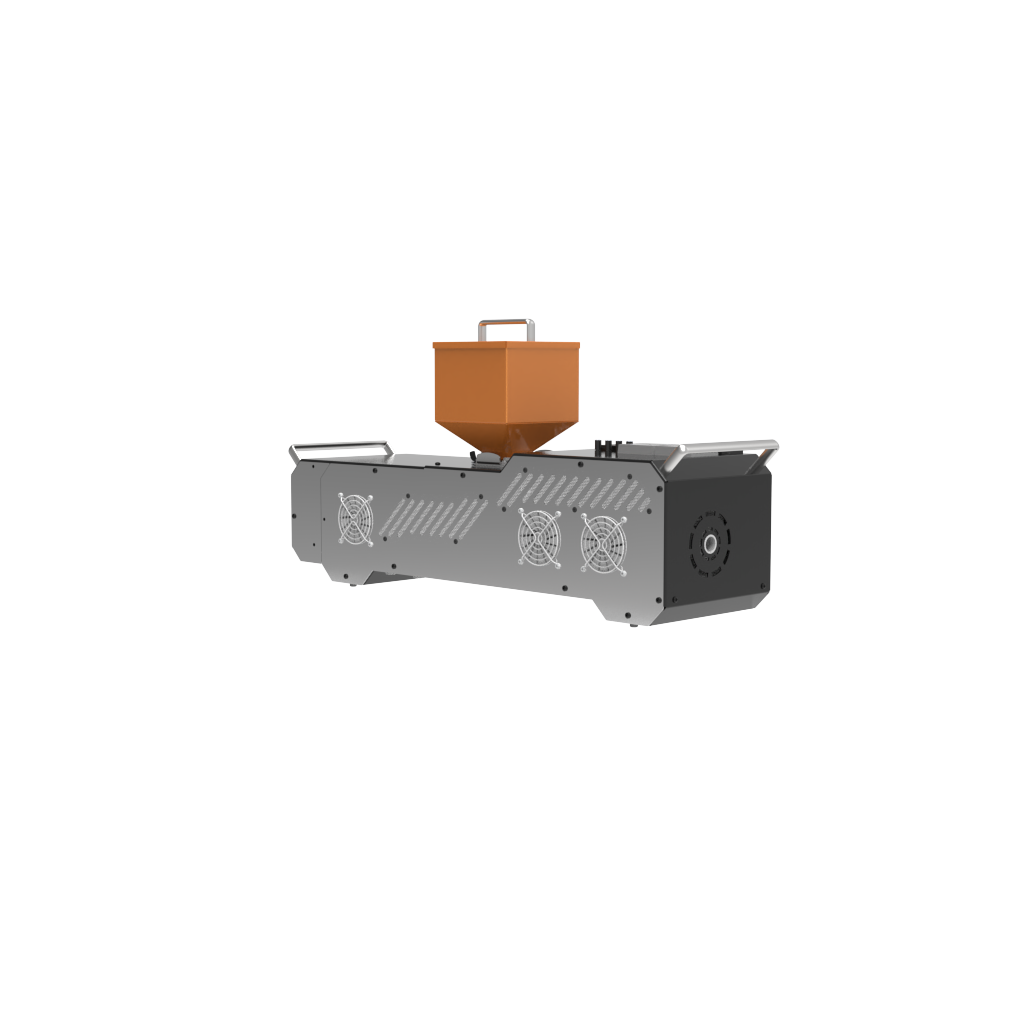

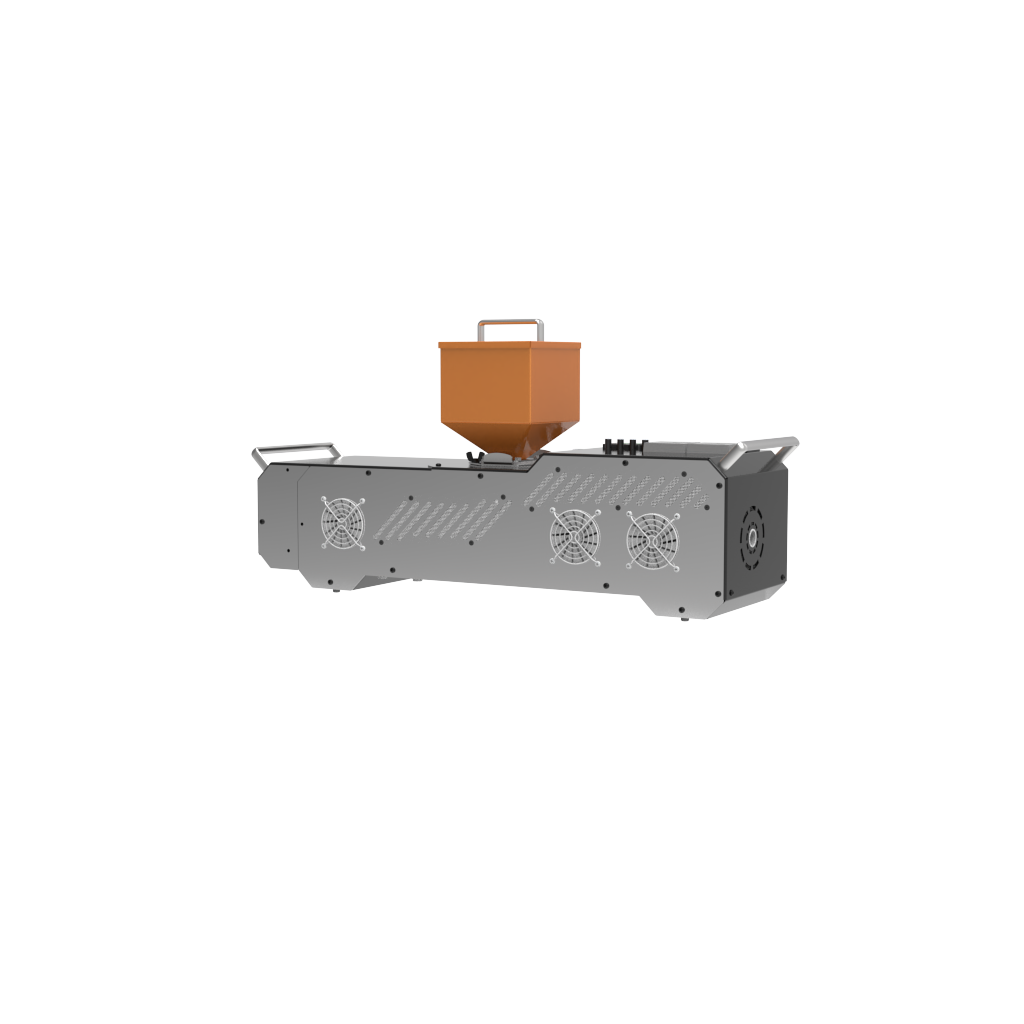

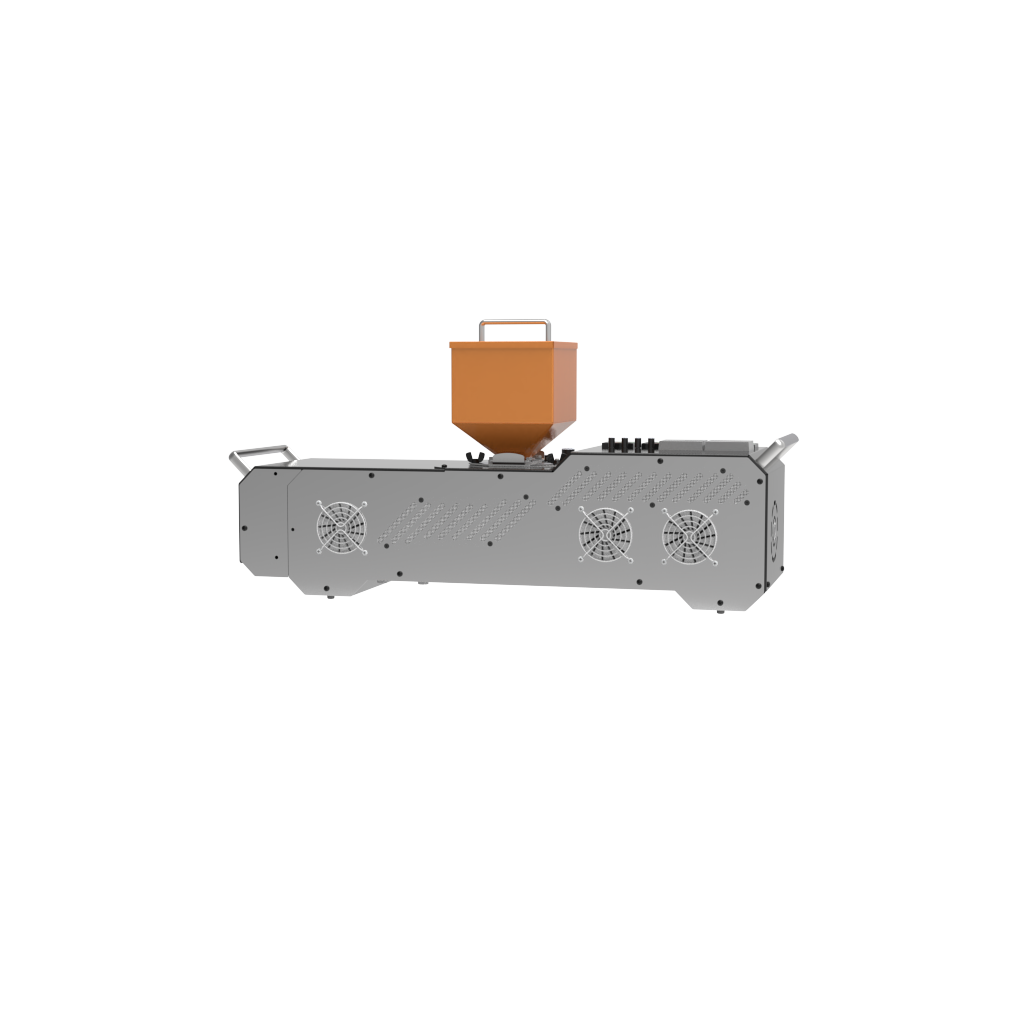

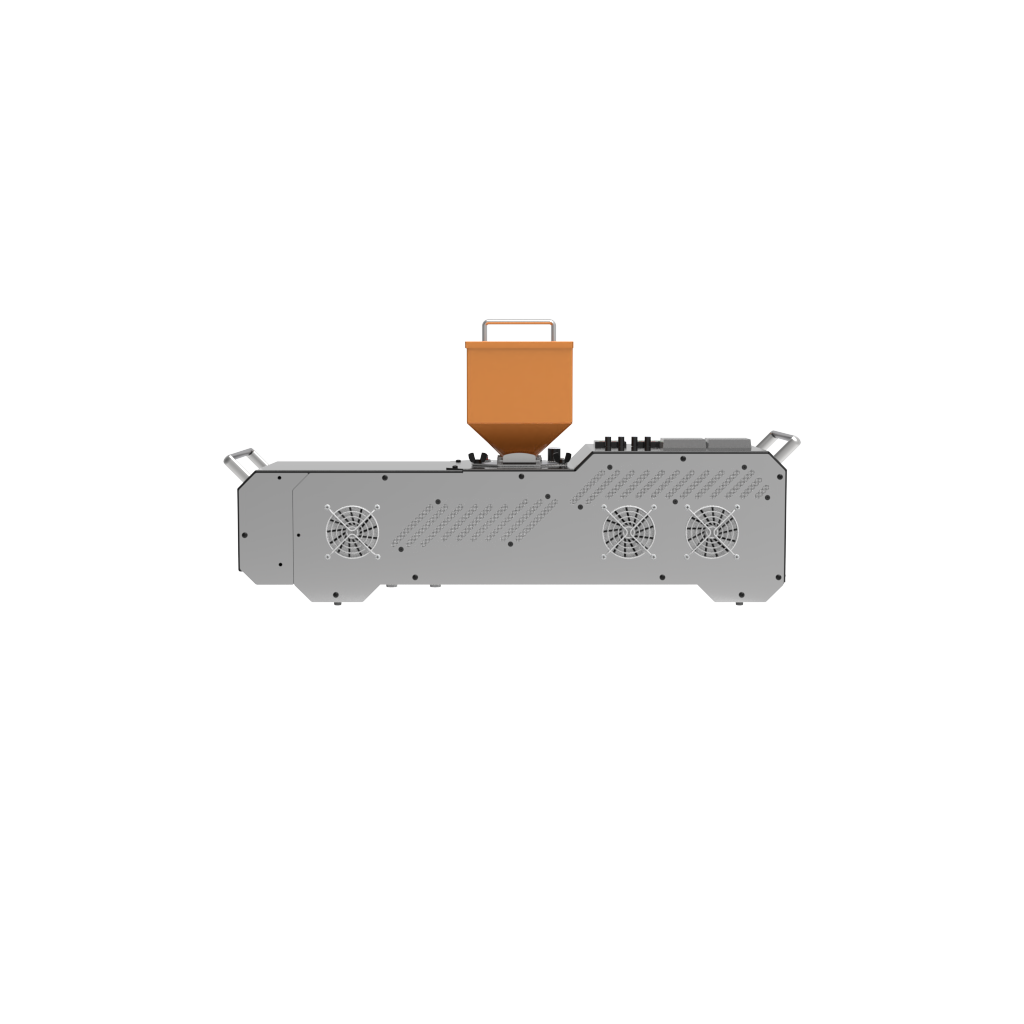

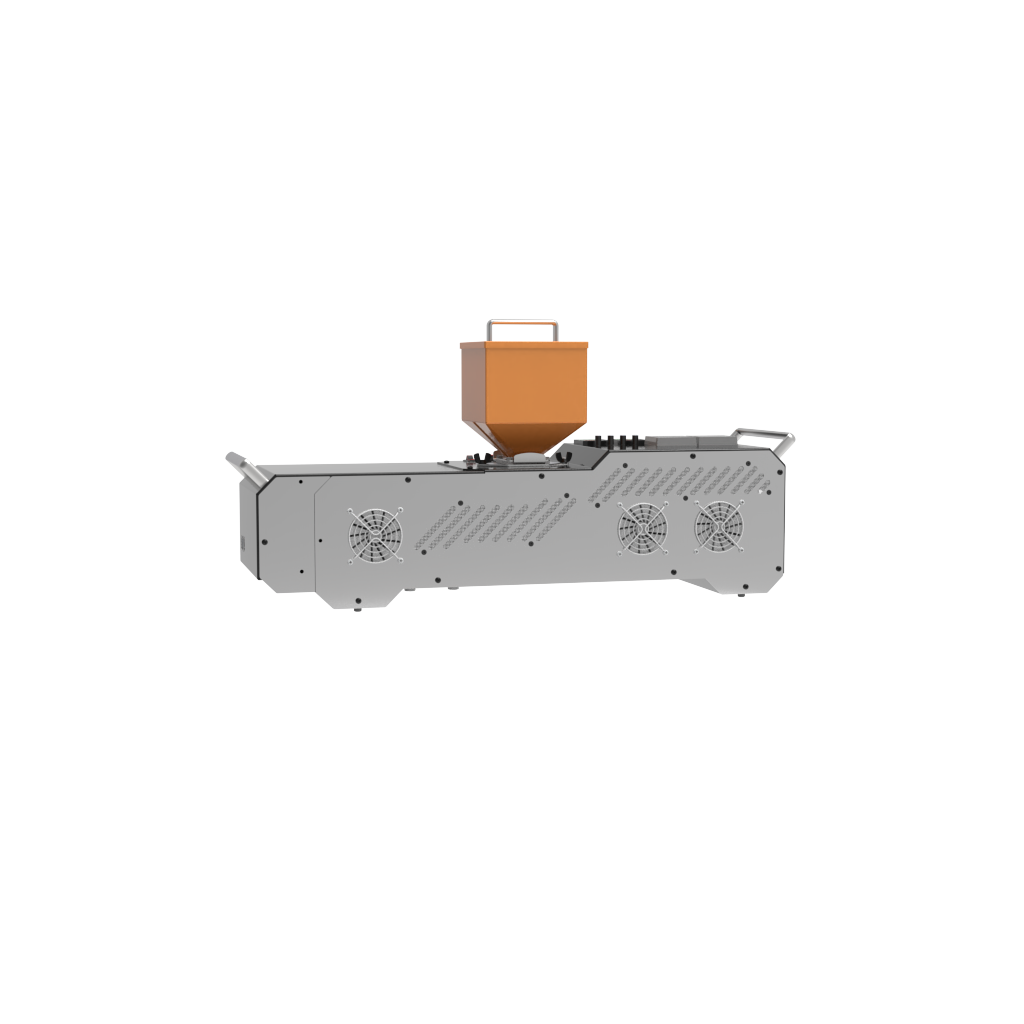

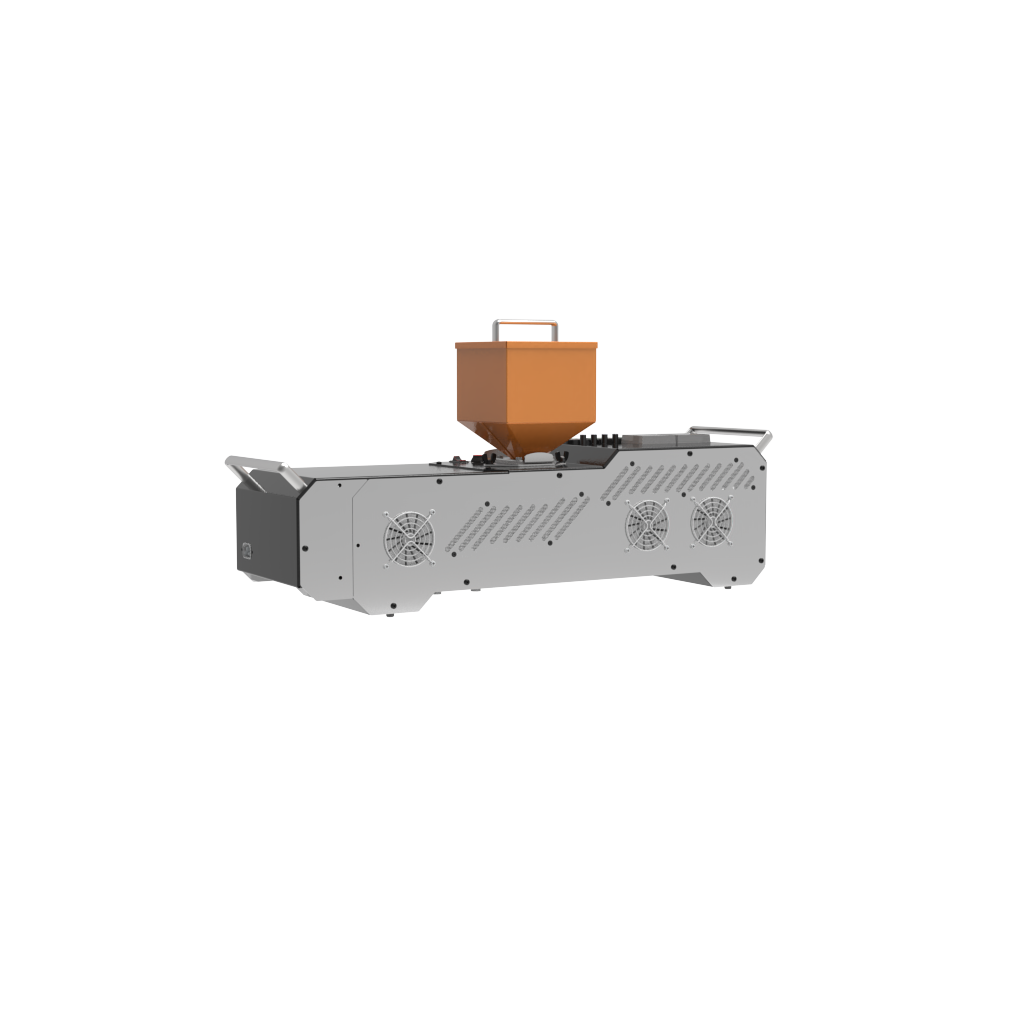

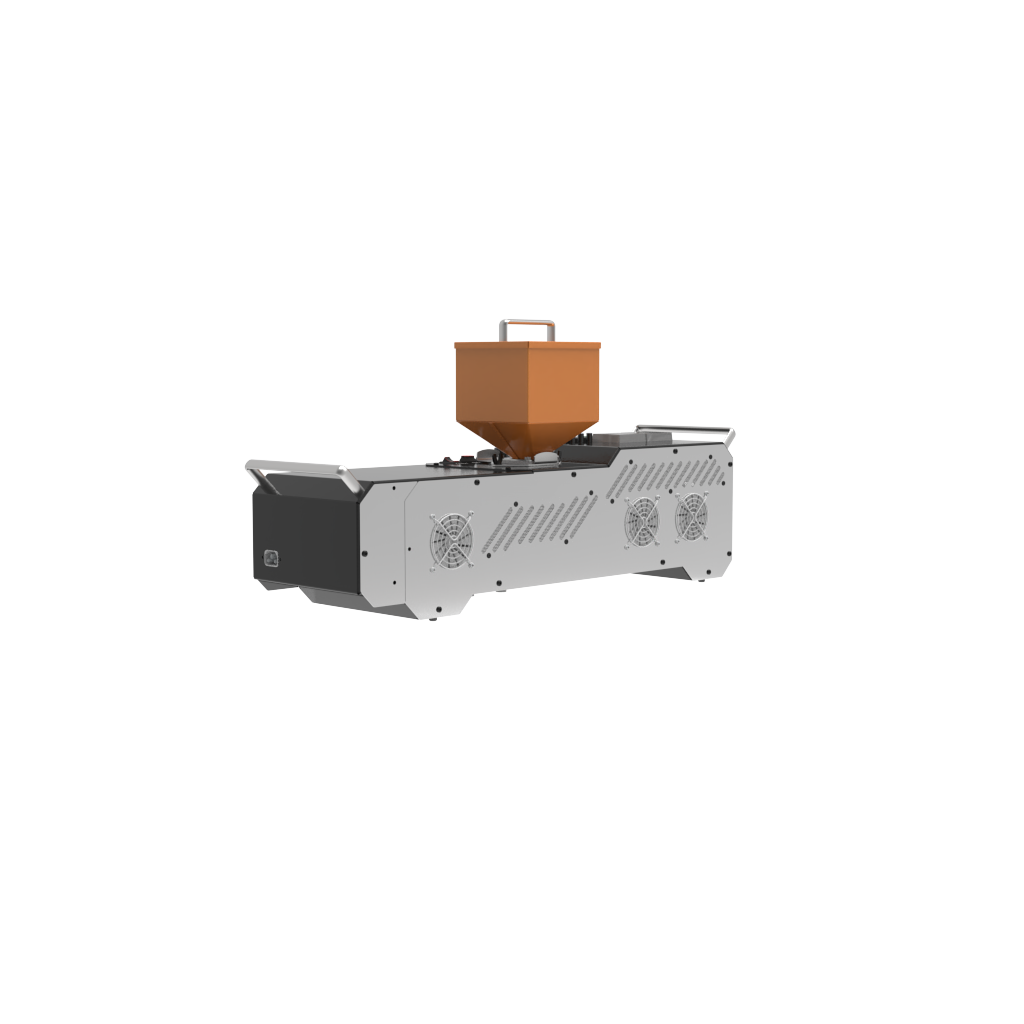

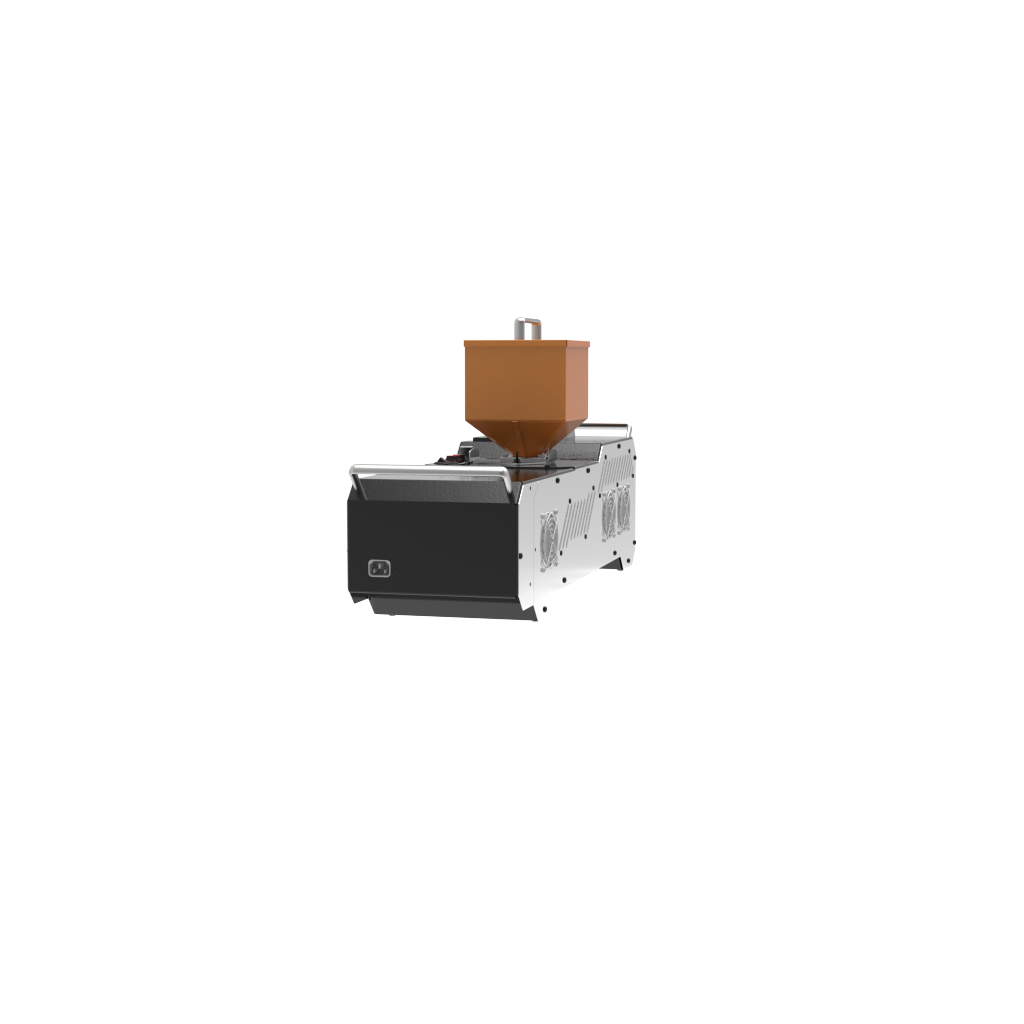

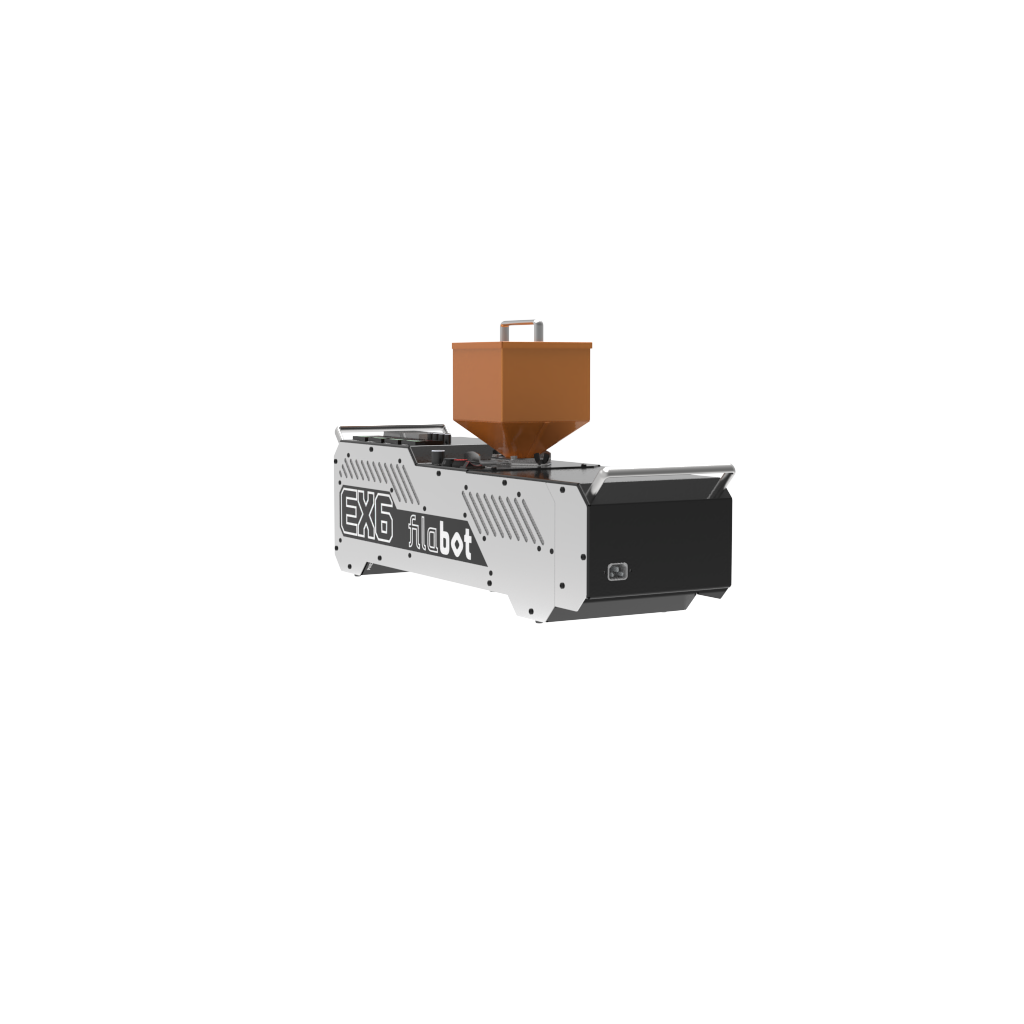

EX6 LS Filament Extruder - Laboratory Series

25% OFF - End of Year Sale

Use code FILABOT25 to save 25% at checkout

This Laboratory Series EX6 has an upgraded barrel and screw that are treated with a nitrated process to bring superior hardness and wear resistance to the system. In addition to this improved barrel system the Laboratory Series has the highest quality power components to ensure highly controlled process parameters above and beyond the Standard Series and Industrial Series Filabot EX6 extruder platform. Instead of switching heaters on and off for heat control, this version ramps up power smoothly and continuously ensuring no thermal shock to polymer being processed. This system is designed for high volume production, extrusion of highly filled polymers, and abrasives. Highly sensitive thermoplastic grades, and advanced extrusion projects.

There is currently a three month lead time on the Filabot EX6 LS.

The Filabot EX6 LS extruder is our laboratory-level system, designed to be the best system for developing new polymers and for production of filament. The EX6 features a three-stage extrusion screw made from hardened and polished high-carbon stainless steel. The screw can be easily removed for cleaning and can be swapped out with the various other screw profiles to match the processing requirements of the polymer. With this new system, screws with different characteristics can be used as needed for each specific polymer, allowing screw designs to be tested and polymer output and consistency optimized. All screws have a 24:1 L/D ratio giving greater versatility and control compared to other extruders.

Click here to learn about the other available screws.

The EX6 features extrusion speed control and a 4 zone temperature control system. The speed control board includes an automatic, variable voltage control module that is engineered to regulate the precise RPM of the screw. The temperature zones are independently controlled allowing for a polymer specific heat profile.

The Filabot EX6 comes with a full one-year warranty on all parts.

Extrudable Plastics: 4043D PLA, 3D870 PLA, 3D850 PLA, Magnum 8391 ABS, and HIPS. Click here for EX6 Extrusion settings. The EX6 is also capable of processing ABS Flame Retardant, PC, PP, PS, ULTEM, PEEK, NYLON, HDPE, PETG, and WAX. Low to Higher Melt Flow Polymers.

Extrusion Rate: Over 11 pounds per hour (5.1kg per hour) - Dependent on polymer properties, filament output speed may be less. Output test is done with 4043D PLA for mass flow rate at the nozzle.

Filament Sizes: 1.75mm and 2.85mm

Material Input Size: 1/8in (3.18mm) pellets to powder

Material Capacity: Hopper - 195 cubic in (3195.5 cubic cm)

Screw Void - 2.37cubic in (38.8 cubic cm)

Feed Port - 195 cubic in (3195.5 cubic cm)

Temperature Control: 4 Independently PID controlled heat zones, all with active fan cooling for consistent heating

Feed Screw and Drive:

0-300rpm Speed Control : Servo Drive

24:1 L:D Ratio Screw

16.28" Length (45.31cm)

5/8” Diameter (16mm)

1/2” Pitch (13mm)

Removable and up-gradable screw

Stainless Steel and Hardened

EX6 Includes

1. Removable Screw

1. 2.85mm Nozzle

1. 1.75mm Nozzle

1. User Manual

1. Power Cord

1. Packet of Anti-Seize

2. Packages of Purge

1. Brass wire wheel,

1. Brass pipe cleaner,

1. 10’ of copper gauze and an extension rod for the pipe cleaner

1. Screw removal tool,

1. Pair of oven mittens.

Extrusion Pressure:

3D870 running 365 - 435 psi

Max (plugged nozzle) 765 psi

Universal Power Input: 110 VAC or 220 VAC - 50 to 60hz - 1550 watts MAXIMUM

Physical Characteristics: Weight 50lbs (23kg) and dimensions of 29.7in x 9.1in x 8.4in (75.44cm x 23.11cm x 21.34cm)

Full 1 Year Warranty

Click Here for the EX6 Dimensions

Click Here for the EX6 G Dimensions

Check out our YouTube channel to see our systems in action!