Filabot

Casting Pattern Recycling Setup

This all-in-one solution is engineered for the efficient recycling of casting patterns used in sand casting and investment casting processes. This comprehensive system combines Filabot's technology to transform used casting patterns into reusable thermoplastic materials, significantly reducing waste and lowering material costs.

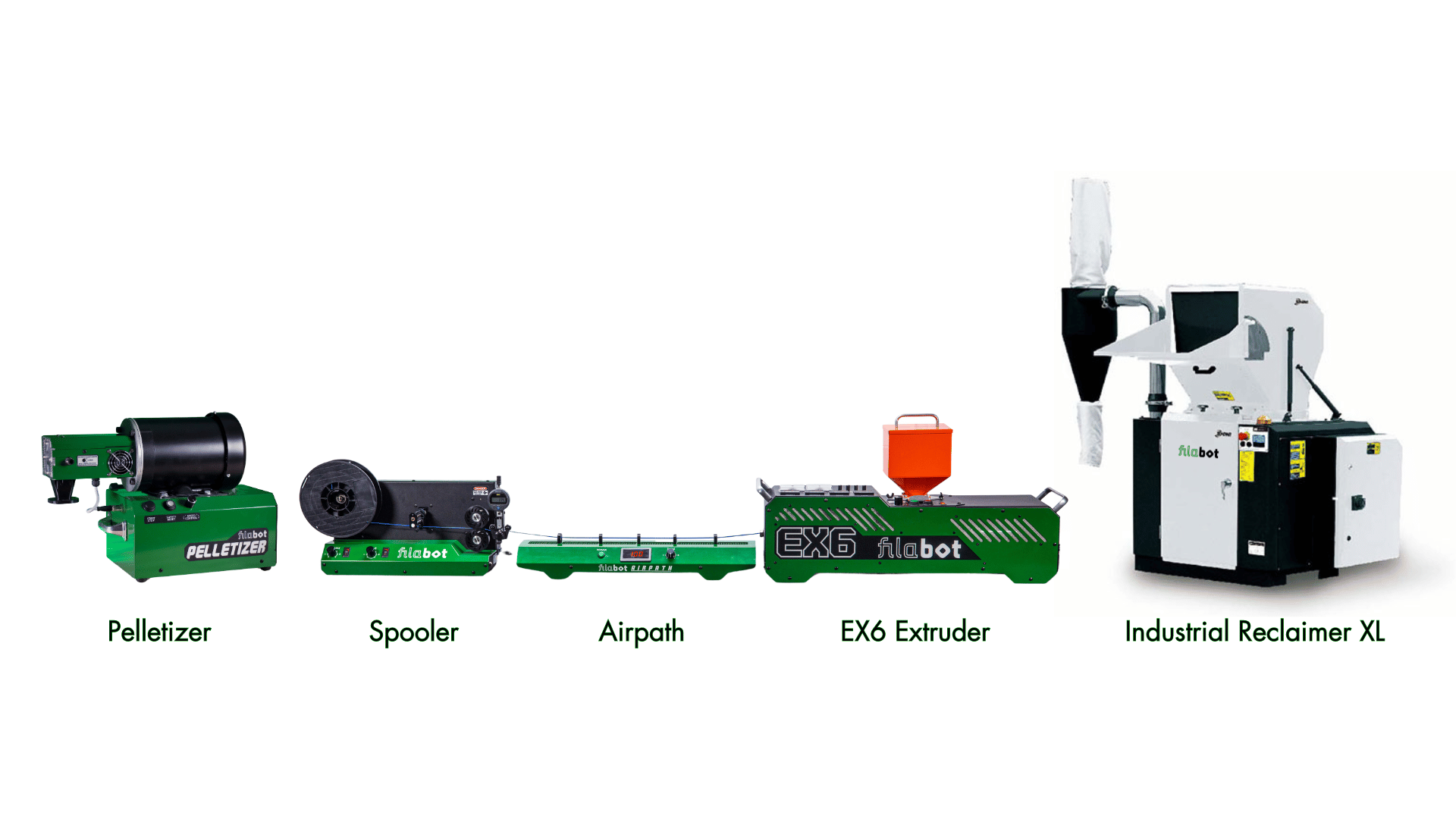

The setup includes the Industrial Reclaimer XL, which shreds and reclaims material from even the most robust casting patterns. We offer two models to fit your specific needs. The first option, with a 7hp motor, grinds up to 250 pounds of material per hour—perfect for medium-sized operations. If you need more muscle, the second model features an 18hp motor, capable of grinding up to 400 pounds per hour, and comes with a larger cutting chamber to handle even bigger jobs.

The reclaimed material is then processed through the EX6 Industrial Extruder, which ensures precise and consistent extrusion of high-quality filament. The Airpath cooling system stabilizes the extruded filament, maintaining its integrity during the process. The Spooler winds the filament onto spools for easy handling and storage, while the Pelletizer converts the material into uniform pellets, ready for use in your next pattern print.

The Casting Pattern Recycling Setup is designed to streamline the pattern recycling process, providing foundries and manufacturers with a sustainable solution to repurpose materials, reduce environmental impact, and enhance production efficiency.

Whether you're dealing with sand casting or investment casting patterns, this setup is the perfect addition to your workflow, enabling you to close the loop on material use and achieve your sustainability goals.