It is hard to believe that in 2011 I started a Kickstarter campaign, which would ultimately lead me to drop out of college and land me here: at Filabot, in my own office, working with a team of brilliant people, recycling plastic. I’m still kind of in awe.

This all started with a vision. I was watching a video before a holiday break, snow streaming down outside, when the idea for the Filabot hit me. If plastic could be used and accessed in a different way, it would change and blow open the possibilities of 3D printing for anyone.

In 30 days the idea of the Filabot raised $32,330 by 156 wonderful backers. At that point it was still just an idea, no prototype, no plan. I owe everything to those people, my first backers. Those 30 days changed my life.

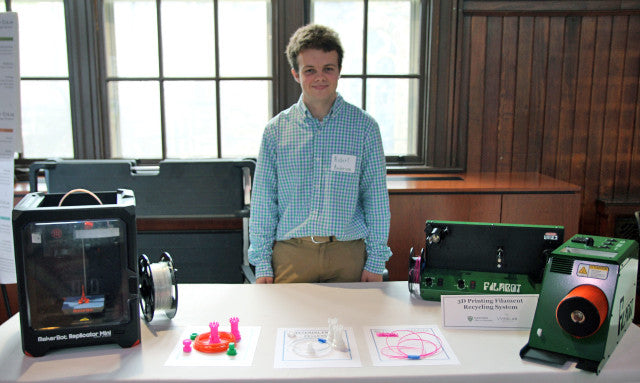

Since our inception we’ve been recognized by so many people. In 2013 we were named one of the top 13 products of 2013 by Sustainable Brands. In 2016 we were named the "2016 Business of the Year" by the Central Vermont Economic Development Corporation. We have been written up in Popular Science, Wired, Techcrunch, etc. and the Filabot was featured on Intel’s “America’s Greatest Makers.”

What none of those awards or write-ups reveal is that the Filabot has gone through maybe 40 prototypes and is still developing. It’s nice to get an award, but that’s like a final draft, a finished end point that neatly hides all the hiccups and development and grease and sweat. We prototype and develop new parts and machines every day. We’re a team of five dedicated members who work at recycling the widest range of plastics possible. That’s what we do, that’s what we’re doing.

Our only mission: To recycle the widest range of plastics possible.

Filabot is changing. It’s gone through a rebrand, site redesign, we’ve hired more people to the team, we ship all over the world, and we have fun. This isn’t about sales, this isn’t about being a CEO, this is about recycling plastic.

Yes, I own a company. But all this company does is allow me to pursue methods of recycling, to refine, develop and then get machines into the hands of amazing people pushing the social side of recycling and waste reduction. We’re makers here at Filabot, and we’re here for makers everywhere.

Right now we have a recycling system that can take waste PLA, ABS, PC, PP, Ultem, and a few others and recycle that plastic back into filament. However there are a few key plastics, such as PET, that we are still working on. Once we can take a soda bottle and turn it into a 3D print our goal will be met. We’ll have to think up bigger ideas. It’ll be great. And it is going to happen.

Everyday I wake up, have a cup of coffee and head to work. But it doesn’t really feel like work. It has never felt like work, it’s always been and continues to be what I do. Everyday is new and different. Deciding what to do with marketing budgets and handling all these new realms of business ownership has been difficult. I learned a lot in those first couple years after the Filabot got backed online. I learned to fail, a lot. I learned to keep failing, and I still learn to be comfortable being uncomfortable. I never knew things would turn out the way they have.

With all these changes, with customers as big as NASA to makers in garages in Tennessee and Tasmania, I wanted to get the story of Filabot out there from my own perspective. We’re gearing up for more big changes, product releases, ideas to demonstrate what is possible with the Filabot.

I wanted to write this letter to say thank you to all the makers out there. The original Kickstarter backers, the people who I talk to everyday that have made my ideas and dreams a reality. What energizes me every day is knowing there are people out there who use our machines to make a difference, who recycle and tinker and are changing the 3D printing industry one spool of filament at a time. The dreamers, the no-sleepers, the men and women who are dedicated to nothing other than the thrill of making.

We’re almost all research and development here in Barre, VT. We’re developing machines that extrude the widest range of plastics possible. That’s what we’re doing, the people and the possibilities are why we’re doing it.

Stay tuned for all that’s coming this summer. We can’t wait to show you what’s next.

Thanks and until next time,

Tyler McNaney

CEO and Inventor of Filabot

3 comments

Chad Z. Dawson

Very inspiring! Keep changing the world.

Very inspiring! Keep changing the world.

Alex Echeverria

Good to read from you! I was a backer and tried to make some filament but had problems with temp sensor. I was able to replace it and then had problems of all sorts. No filament but learned about this peculiar technolofy. I admire your stamina and talent with the tricky material plastics are. Keep schredding and extruding!

Good to read from you! I was a backer and tried to make some filament but had problems with temp sensor. I was able to replace it and then had problems of all sorts. No filament but learned about this peculiar technolofy. I admire your stamina and talent with the tricky material plastics are. Keep schredding and extruding!

Linell K Pierce

Wow. You’ve done amazing things already. It’s so exciting. Continued good luck!

Wow. You’ve done amazing things already. It’s so exciting. Continued good luck!