Materials science is currently experiencing a notable shift, partly due to the integration of technologies such as the Filabot extrusion system, the MDAC1, and collaborative robots (cobots). This combination is enhancing research and development, leading to innovative applications across various industries. In this post, we will discuss how these technologies are collaboratively contributing to the evolution of materials science.

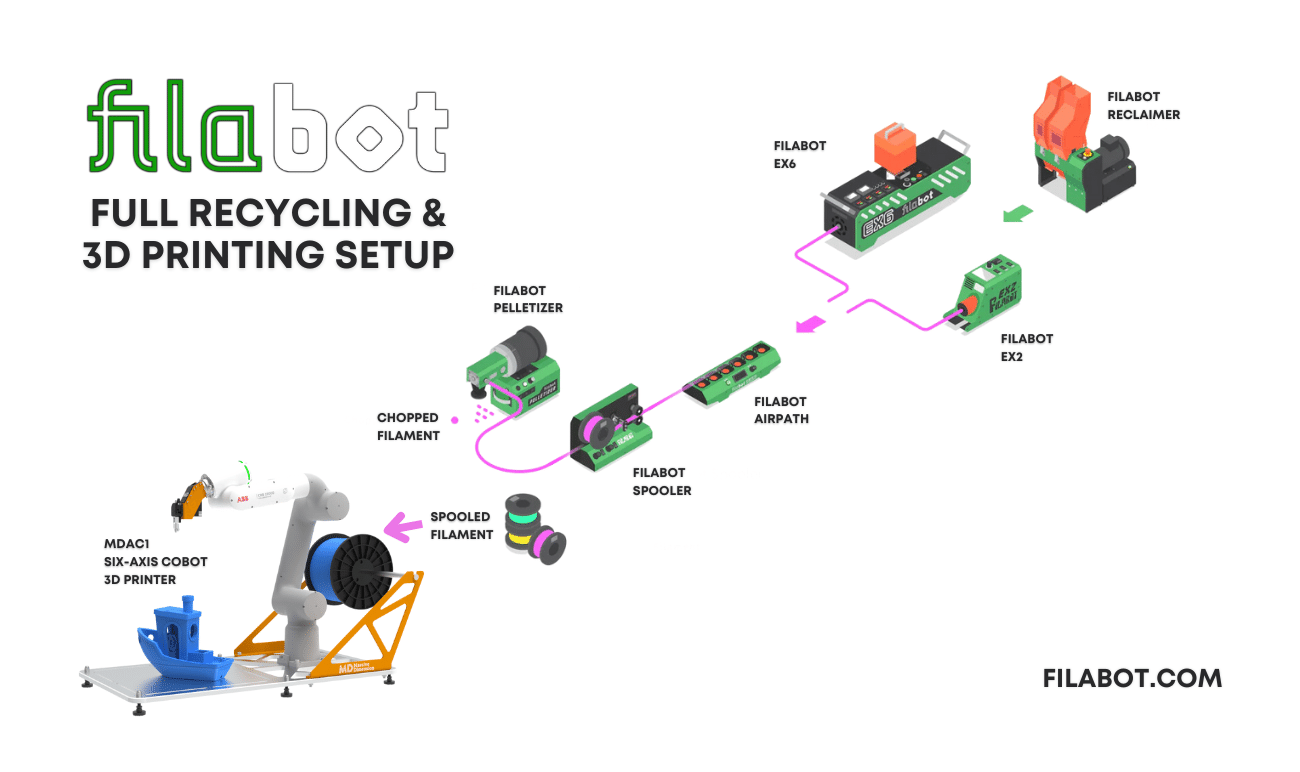

Get these products together in one bundle here: Full Recycling & 3D Printing Setup

Understanding the Role of the Filabot Extrusion System

The Filabot system has been a helpful addition to the field of 3D printing and materials research. Its ability to convert plastic waste into usable 3D printing filament is a step towards more sustainable material usage. It is particularly useful in materials science for creating custom filaments with specific properties, aiding in the exploration and development of new materials.

Key Contributions:

- Sustainable Material Development: Filabot plays a part in eco-friendly research by recycling plastic waste, thus minimizing material consumption.

- Custom Filament Creation: It offers the possibility to develop materials with unique properties for specific uses.

- MDAC1: Enhancing Precision and Efficiency

The MDAC1, a noteworthy development in advanced robotics, contributes to precision and efficiency. Its design is suited for delicate tasks, making it a suitable tool for handling and testing materials, especially those developed using the Filabot system.

High Precision Handling: Crucial for experiments with delicate materials.

Efficient Material Testing: Automates and simplifies the testing process.

Exploring the Role of Cobots in Materials Science

Cobots are increasingly important in laboratory settings, particularly for their ability to safely and efficiently assist human researchers. In materials science, they are useful for automating routine tasks, managing hazardous materials, and ensuring consistency in experiments.

Cobots' Contributions:

- Automating Repetitive Tasks: Helps in increasing productivity and maintaining consistency.

- Enhanced Safety: Manages hazardous or sensitive materials, reducing human risk.

- Flexibility: Can be reprogrammed to meet various research requirements.

The fusion of the Filabot system, MDAC1 represents a significant collaboration in materials science R&D. This synergy streamlines the process from material creation to testing, fostering efficient and innovative research.

The combination of the Filabot system, MDAC1 is an important step forward in materials science R&D. This collaboration not only supports sustainable and efficient research practices but also opens new avenues for material innovation. As these technologies continue to develop, their role in shaping the future of materials science and related fields is likely to be increasingly significant.