If you've been following this blog you know that at Filabot, we have fun. And when we aren't doing the work we're supposed to be doing we're taking advantage of our various printers, filaments and machines.

Working on your side projects is encouraged here. Reason #31 of why it's such a great place to work.

This week we thought we'd carry on the vehicle vein and talk about another employee and his quest for a better vehicle. Our lead engineer Kevin Orth has printed a custom tail light for his truck. And while his truck is sometimes operational, this tail light design has worked out great so far.

3D printing is great for producing quick runs of identical custom parts and Kevin is able to match and design almost anything (or download it from thingverse). Like a savant listening and playing back a song he's just heard, Kev can look at something once and devise a way to design and duplicate. With 15 minutes of design time and about 50 minutes of printing a quick but durable solution is possible and that's what this tail light represents.

BAM: A strip mount tail light for Kev's truck!

Ain't it purty? For all of you wondering:

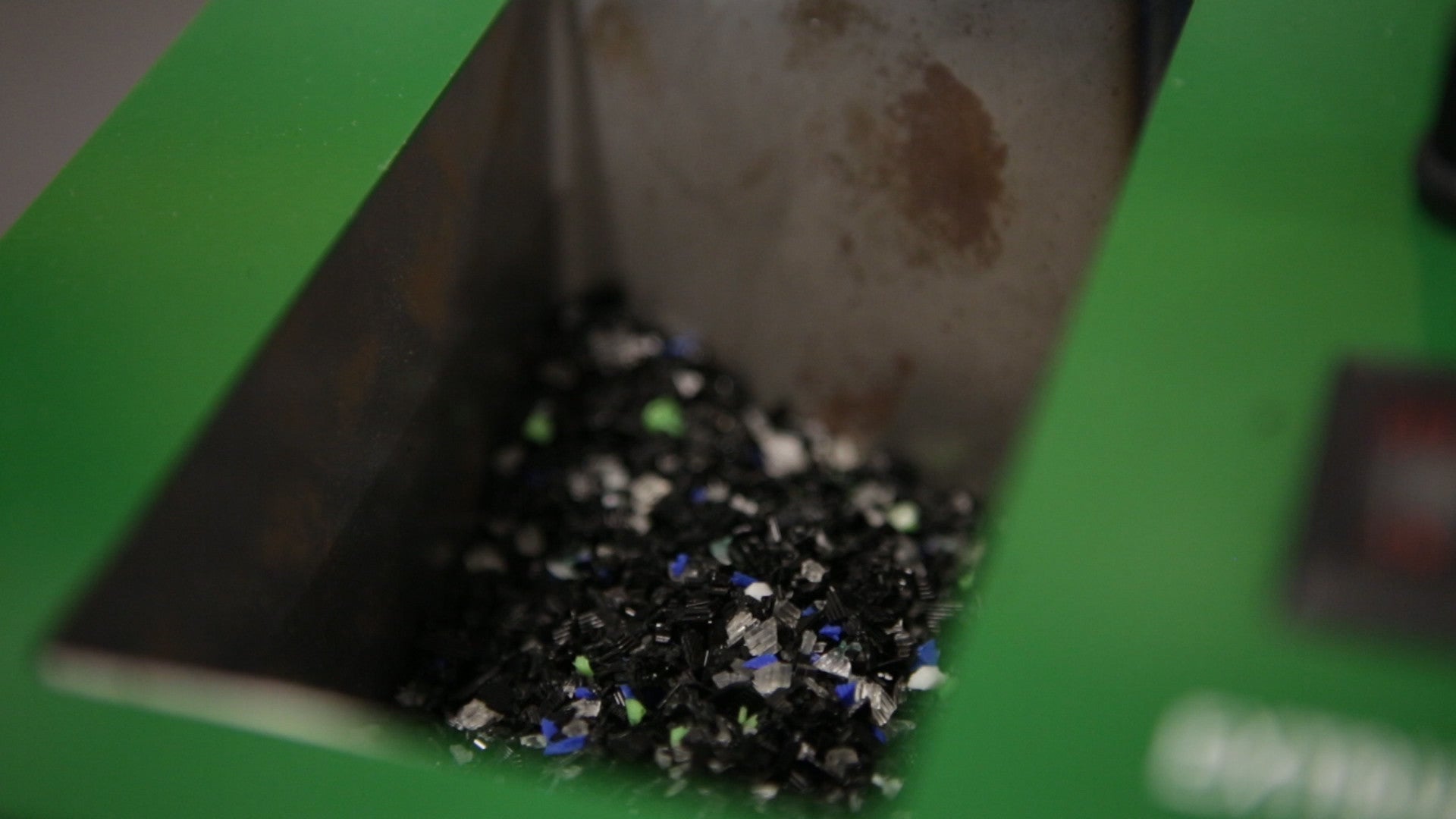

What you see in the pictures are red colored PETG with no UV stabilizer additive. What's great about Kevin repairing his tail light is that we plan on seeing how well it performs outdoors because, as you may well know, PETG is susceptible to UV damage.

At Filabot, we're currently sourcing a UV stabilizer additive: seeing & testing how durable it is. More on that in the coming weeks.

Anyway, what do you print? Share your stories, failures, successes, whatever! We'd love to hear what you're up to, especially if you're using Filabot filament!

Thanks for reading,

The Filabot Team